Page 10

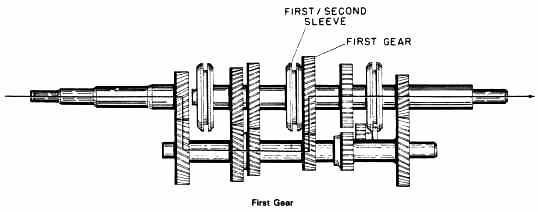

First Gear (See First Gear Figure)

When the shift lever is placed in first position, the first/second sleeve is moved rearward on the main shaft. In between and perpendicular to the fork shafts are detent dowels and pin which prevent two gears from being engaged at the same time. The sleeve contacts the synchro, which is normally kept out of contact with the first gear by the spring between the synchro and first gear.

As the synchro contacts the sleeve, friction between the synchro and the conical surface forces the sleeve (keyed to main shaft), synchro, and first gear (being turned by the countershaft) to approach the same speed. Drive is finally achieved when the crown teeth inside the sleeve engage the crown teeth on first gear.

Once fully engaged, the spring between the gear and synchro, would return the sleeve to neutral. This is prevented by the spring loaded detent balls engaging notches in the fork shafts.

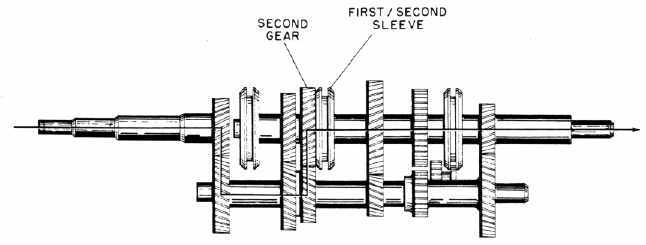

Second Gear (See Second Gear Figure)

When the shift lever is placed in second position, the first/second sleeve is disengaged from first gear, then engaged with second gear. Synchronizing is the same as for first gear.