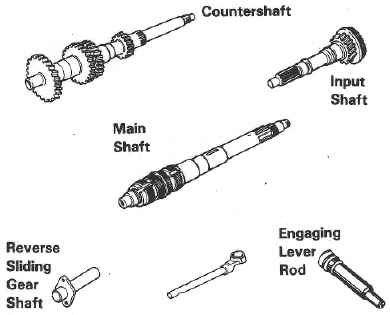

Input Shaft, Main Shaft, Countershaft, Reverse Sliding Gear Shaft, and Engaging Lever Rod

a. Check all shafts for straightness

by placing be-

tween points. Maximum runout shall be not

greater than 0.002 inch. Some shafts can be

straightened with a press. I If not, replace.

b. Check splines for damage. Use a fine file, emery, or

stone to remove burrs or nicks.

c. Check that threads on main shaft and counter-

shaft are not damaged. Replace shaft if threads

are stripped.

d. Check that bearing surfaces are free from burrs, nicks

or galling. Use a fine stone or emery to clean.

e. Check engaging lever rod for straightness and wear. Replace

if worn or bent.

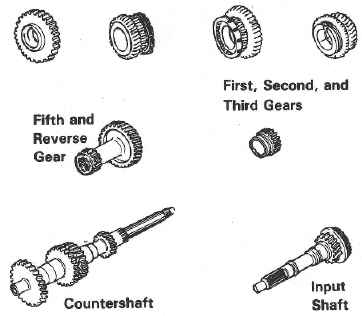

Gears

a. Check that teeth on all

gears are not chipped, broken, or

galled. Replace if damaged.

b. Check that synchro crown teeth are flat and not rounded.

Rounded teeth indicates worn gear. Replace.

Also replace

mating gear.

c. Check that wear pattern is even. Replace if worn.d.

Check that bearing surfaces are free from burrs,

nicks or galling. Use fine emery to clean.e.

Check

that clearance between reverse sliding gear

bushing

and reverse shaft is 0.002 to 0.004 inch.

Replace

bushing if worn.

f. Check that clearance between first gear and its

bushing is 0.002 to 0.004 inch. Replace

if worn.

g. Check that clearance between second and third

gears and seats on main shaft is 0.002 to

0.004

inch. Replace if worn.

a. Check that synchro is not cracked. Replace if

cracked.

b. Check that teeth are not broken. Replace if broken.

c. Check bearing surfaces for excessive wear. Replace

if worn.