|

Before inspecting: a. Clean all parts with a suitable

cleaning solvent to remove oil traces. |

|

|

|

|

|

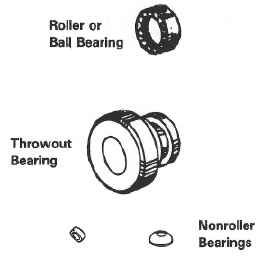

Inspect and repair each part as described. If there is doubt as to a part's serviceability, replace the part. Bearings

|

|

Page 27

|

Before inspecting: a. Clean all parts with a suitable

cleaning solvent to remove oil traces. |

|

|

|

|

|

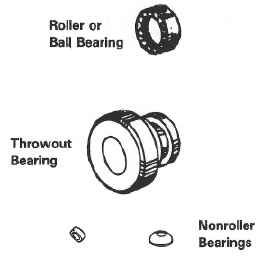

Inspect and repair each part as described. If there is doubt as to a part's serviceability, replace the part. Bearings

|

|